【 微信扫码咨询 】

【 微信扫码咨询 】

Analysis on the reasons for the unsatisfactory filter effect of printer filter supply company.

Choosing anthracite and quartz sand as filter material, because the small particle size will increase the running resistance, in the case of backwashing is not complete, the phenomenon of filter material compaction, resulting in poor filtering effect.

See whether the problem of backwash strength,. Backwash strength = backwash volume (L)/filtration area (m2) × washing time (s). Backwashing strength requirement can not exceed the upper filter material (eca) allowed by the flushing strength, and to ensure that the lower quartz sand has enough backwashing time, rinse, backwashing intensity is too big to run material, strength is too small will wash not clean, moisture mixed wash the intensity of the control will lead to improper medium filter backwash in mixing process.

Printer filter mesh supply company for filter mesh filter effect is not ideal analysis.

The filter head plays an important role in the poor filtration effect. If the selected plastic material is not strong enough, the filter head is likely to be damaged in the work, resulting in the loss of filter material and poor filtration effect.

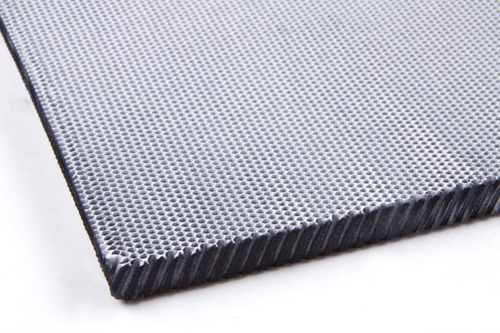

Finally, when using the filter, we should pay attention to the occurrence of the filter material compaction, running material serious, poor filtering effect, every 6 months to 1 year must be replaced filter material, and the water quality fluctuations, oil removal effect is not good. The filter screen of our factory is located in the suction pipe of the pump to remove the residual pollutants in the oil tank which enter through the air hole and protect the pump. But in order to avoid the pump cavitation phenomenon, must pay full attention to the pressure loss, generally used 100-200 purposes of thick metal mesh or notch wire material. Therefore, it is not a filter to control the contamination concentration of the system.

版权所有:苏州贝森环保科技有限公司

技术支持:易动力网络